Description:

This comprehensive text presents the subject of metalworking by offering a clear account of the theory and applications of metal forming processes relevant to engineering practice. It is designed to serve as a textbook for undergraduate and postgraduate students of mechanical engineering, production engineering, industrial engineering, and metallurgical engineering.

The first seven chapters are devoted to basic concepts to equip the students with the background material on mechanics, material sciences and to provide them with a sound foundation in the theory of plasticity. In addition, the importance of friction and lubrication in metal forming processes is adequately highlighted. In the next nine chapters the reader is exposed to a richly detailed discussion of specific forming processes (including the lubricated metal forming processes) and new and powerful techniques are presented (load bounding and slip line field) for solving engineering problems in metal forming. The book then moves on to forming of polymers and also covers metal powder preforms, highlighting recent developments.

In the concluding portions of the book, the important factors such as force, power requirements, formability and machinability in the study of individual processes, are briefly discussed. Finally, the application of computer-aided analysis in the metalworking processes has been demonstrated, being the demand in this competitive scenario. Several chapter-end exercises are included to aid better understanding of the theory.

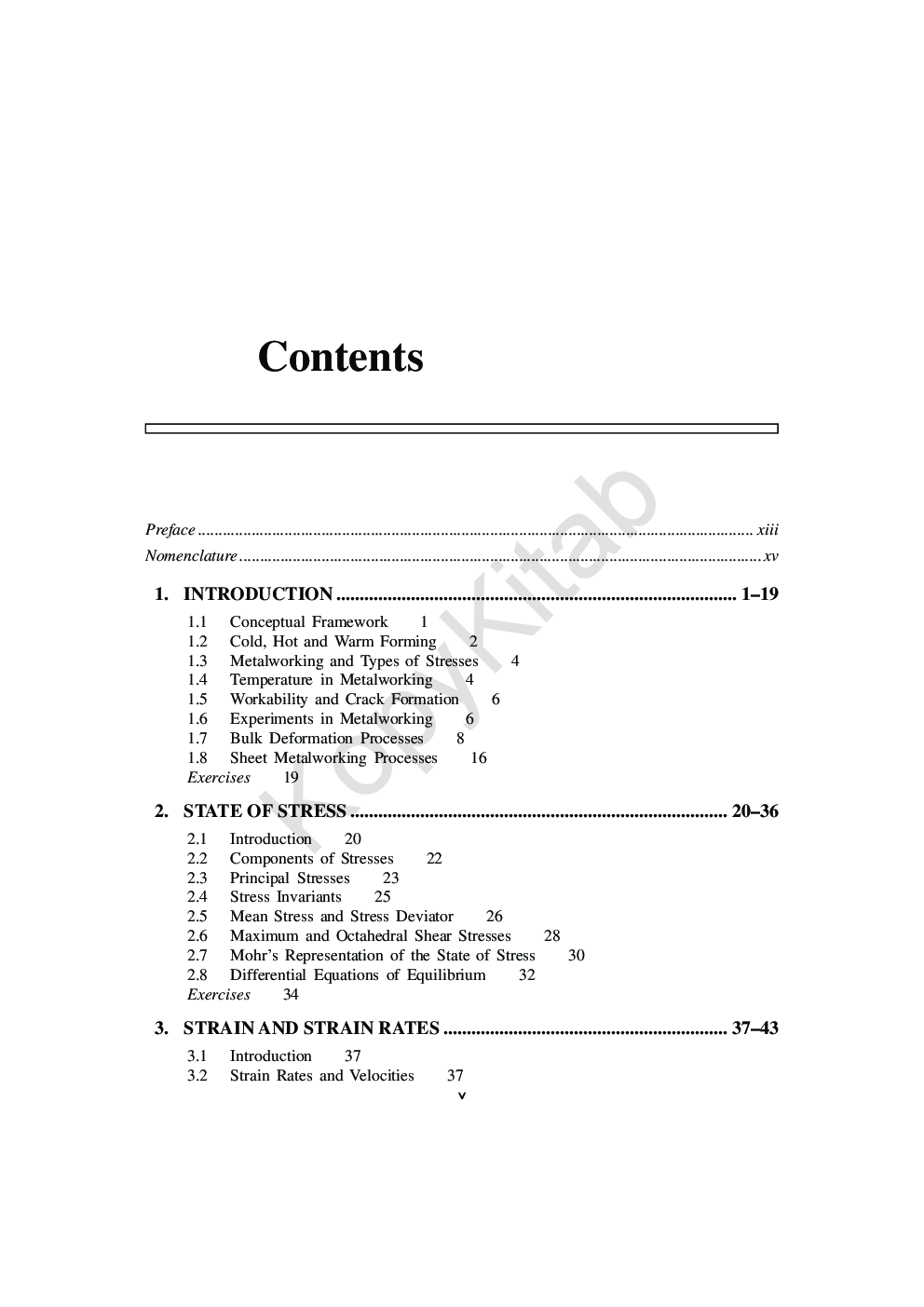

CONTENTS:

Preface • Nomenclature

1. Introduction

2. State of Stress

3. Strain and Strain Rates

4. Stress–Strain and Stress–Strain Rate Laws

5. Yield Criteria and Flow Rules

6. Friction in Metalworking

7. Lubrication Mechanism and Metalworking Lubricants

8. Drawing and Extrusion of Cylindrical Bodies

9. Drawing and Extrusion in Plane Strain

10. Deep Drawing

11. Strip Rolling

12. Forging

13. Bending and Forming

14. Slip Line Field Technique

15. Load Bounding Technique

16. Lubricated Metalworking Processes

17. Cold Processing of Polymers

18. Processing of Metal Powder Preforms

19. High Energy Rate Forming

20. Advances in Material Processing

21. Computer Application in Metalworking

Appendix A Comparison of Various Methods of Analysis of Forming Load

Appendix B Derivation of Reynolds Equation for Power Law Fluids

Appendix C Useful Tables

Appendix D Stress–Strain Curves for Various Materials

References/Bibliography • Index